Essential Benefits of Digimarc Automate

Manually check select packages, cases, or pallets for inaccurate labels

Use machine readable codes to ensure product labels and other components correctly match

Do not monitor label accuracy

*Based on a Digimarc-commissioned Packaging World survey of 200 companies

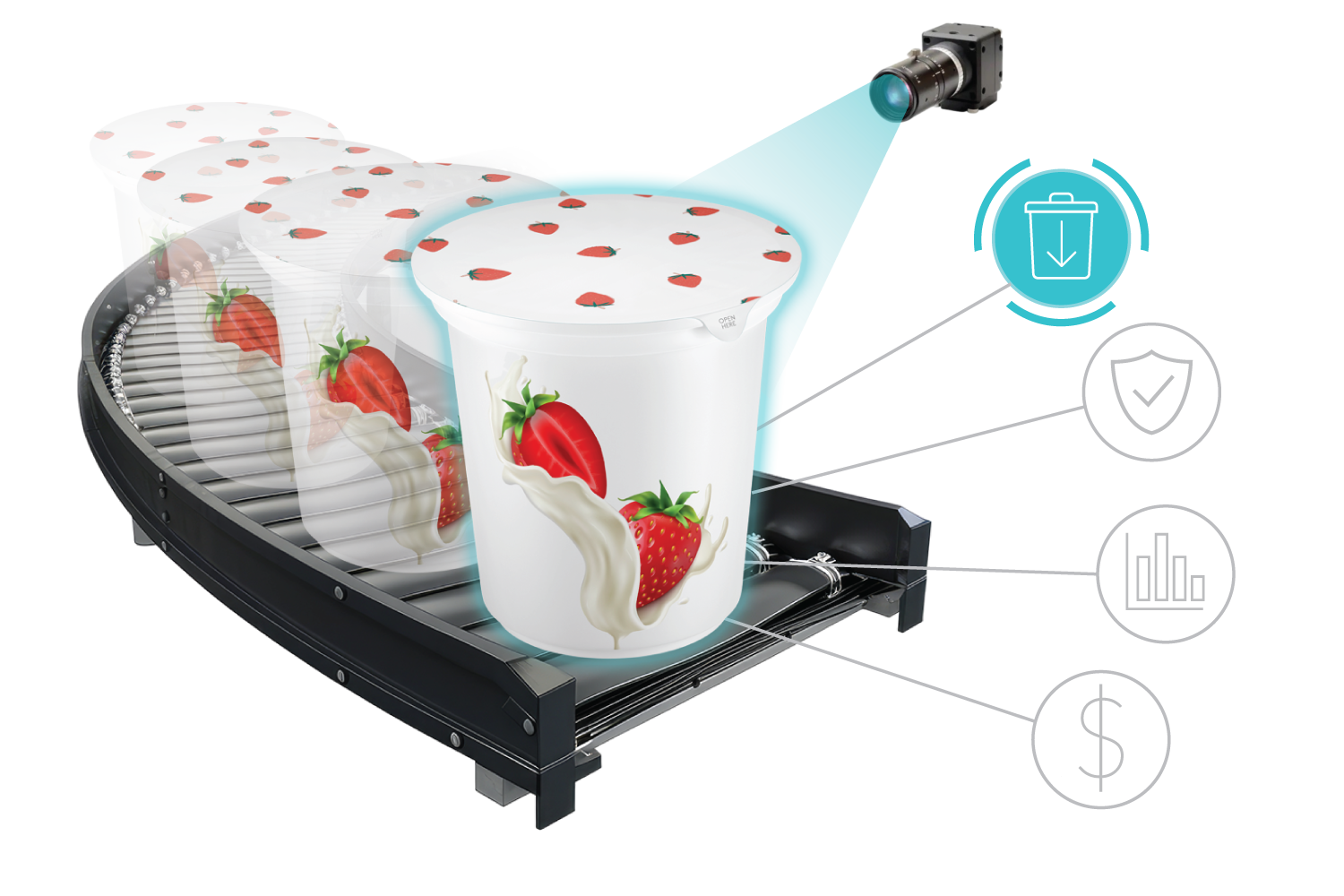

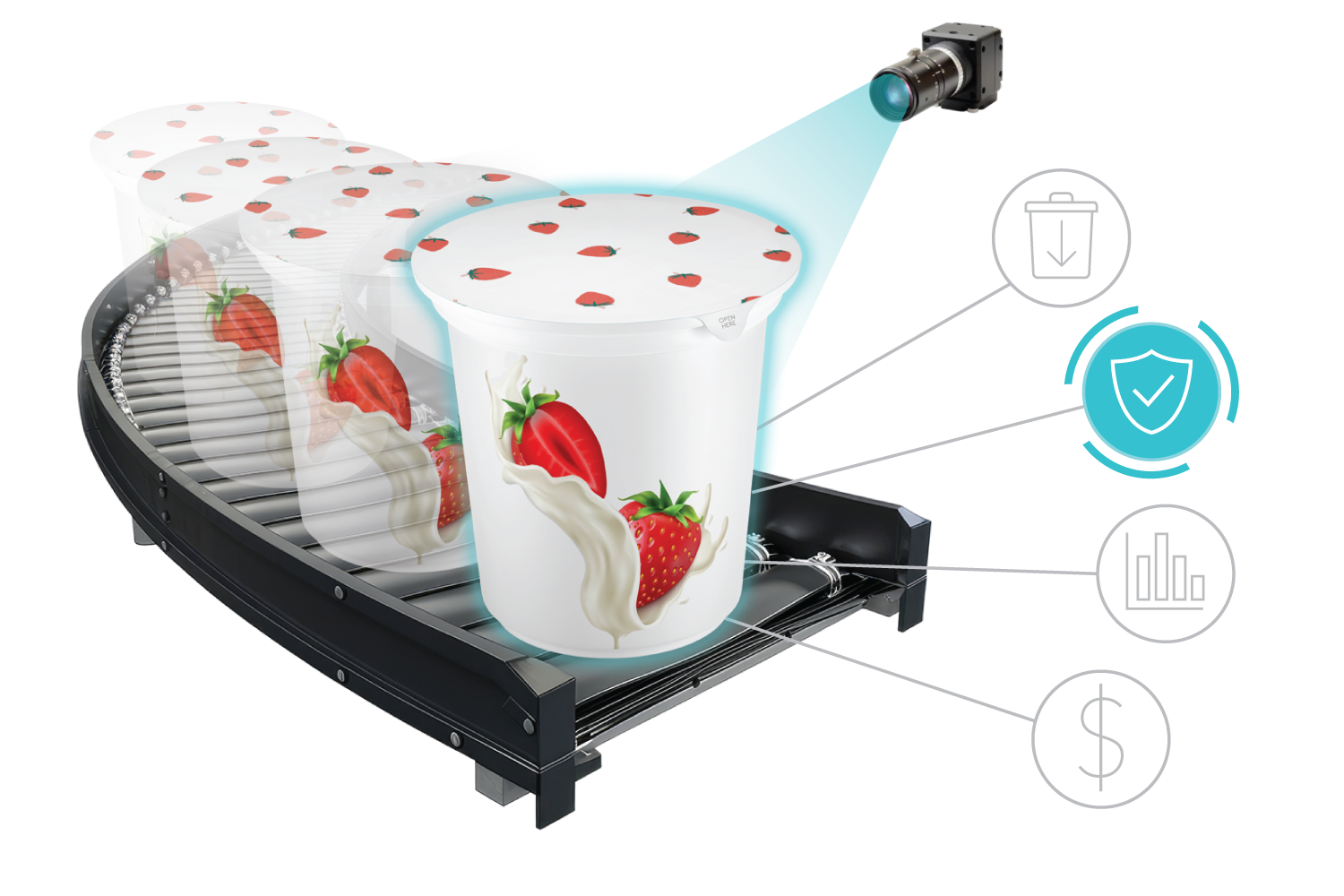

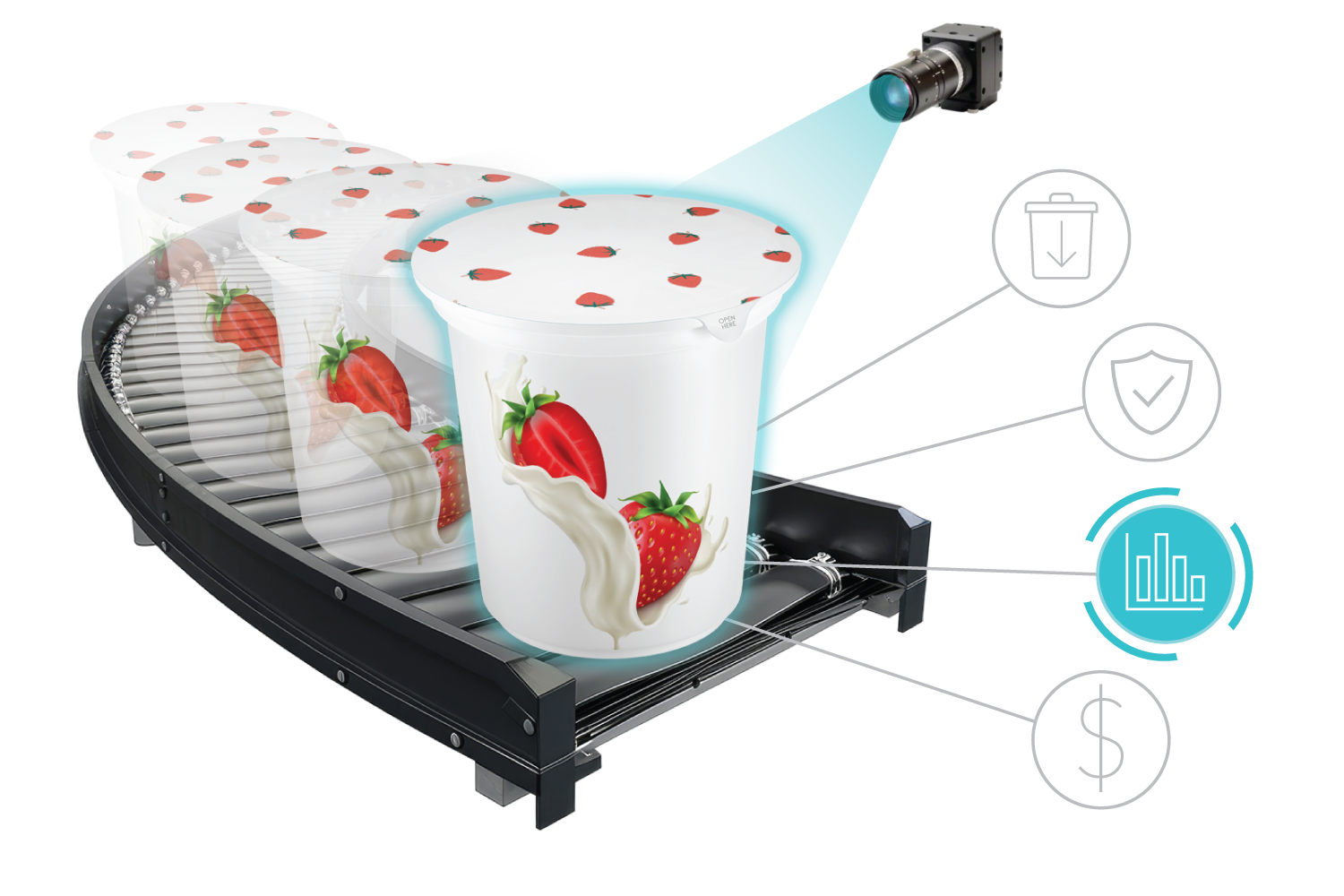

Digimarc Automate in Three Steps

1. Enhancement

Your premedia or print partner embeds digital watermarks into your product, product label, or product packaging.

2. Detection

Your system integrator configures standard vision systems with integrated digital watermark detection OR configures a centralized system using cameras and digital watermark detection on a central controller.

3. Identification

Activated camera systems will detect the digital watermarks quickly and accurately, providing real-time data to foresee problems before they escalate, reducing the risk of faulty products and optimizing production processes.

Key Features of Digimarc Automate

Performant

High data redundancy and repetition of imperceptible Digimarc digital watermarks increases scan performance even in challenging environments such as recycle sortation and frozen food processing.

Efficient

The integration of Digimarc digital watermarks leverages your existing packaging tools and workflows, with Digimarc detection software easily deployable across various camera and inspection systems.

Adaptable

Beyond industrial automation, Digimarc digital watermarks support other enterprise use cases, including product authentication, advanced consumer engagement, improved sustainability, and next-gen retail checkout.

Where Digimarc Outperforms

Digimarc digital watermarking provides a clear advantage over other auto-ID solutions in specific environments and product formats.

Non-uniform or Random Pack Formats

Digimarc digital watermarks excel for packaging formats that cause random orientation on production lines (e.g., cylindrical, irregular-shaped items, thin flexibles), where other solutions are known to underperform.

Design and Branding

For brands prioritizing design aesthetics and brand consistency, imperceptible Digimarc digital watermarks are preferred over multiple visible codes, especially on small products with limited space.

Tough Industrial Environments

In environments where products face physical damage, code occlusion, or poor scanning conditions, the high redundancy of Digimarc digital watermarks ensures superior performance compared to visible codes

High-speed, High-risk Manufacturing

Digital watermarks are ideal for multi-variant products produced in high-volume, high-speed production environments, where the risk and cost of matching errors are significantly higher than in low-volume settings. In cases where an item’s scarcity contributes to its value, such as exclusive limited-run products and collectibles, digital watermarks can be used to precisely identify unit volumes and prevent damaging over-production or inaccurate allocation.

Digimarc + OMRON: Modernizing Digital Product Identification

Digimarc and Omron’s innovative approach leverages unrivaled expertise in digital watermarking and machine vision technology to deliver a transformative new force in industrial automation.

Related Resources

See Everything, Achieve Anything™

With visibility into everything, you gain critical intelligence to guide you in ensuring authenticity, reducing costs, increasing operational agility, and improving circularity at every step along the supply chain. Get started today.